This is about assembling five PCBs yesterday that shared an IC and how, despite meticulous application of solder paste, reflow profile, yada yada, two of five didn’t pass FAT (final assembly test via a simple computer program and microprocessor). Late in the day a little light bulb glowed with faint neon letters spelling “popcorn.” This is the slang for when trapped moisture in an IC explosively changes to steam in the reflow oven, physically damaging the part. The part in question had been away from desiccants for months, the humidity in the shop is far from Arizona levels, etc. I don’ t have the equipment to determine if this damage happened, the budget involved can’t cover sending the board off to be studied, etc, so I just have to assume this is a “maybe” cause of my failures.

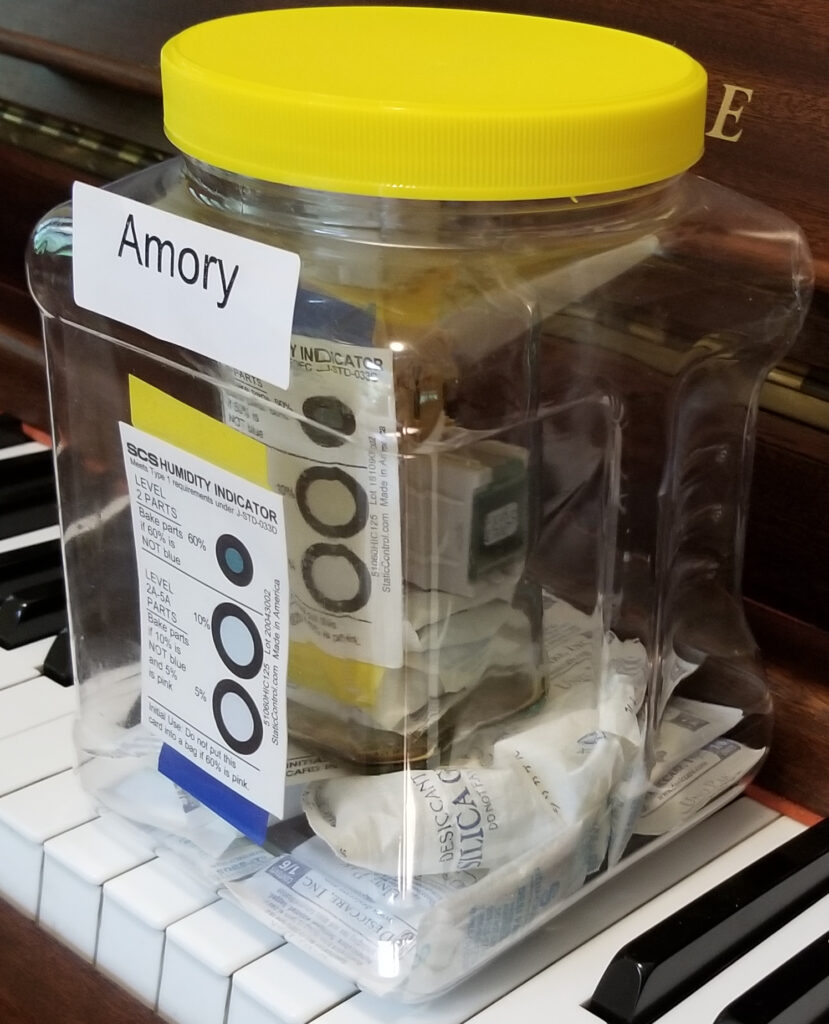

So I followed the specs for “baking out” the moisture and set up these chips with some others that need to stay dry or be in line for baking out and thought I’d share a snapshot. (Click on it to get a better version, and click on that for full resolution. The inner card color dots are distorted: they are actually blue). You know how we get desiccant bags and moisture card from places like DigiKey and toss them? I saved enough over the years to combine them with a cat treat container and Indian sauce jar to make a two level dry air environment. All the bags and some of the chips went through the bake out process (I used 125C for 12 hours). The outer card will let me judge how well the cat treat container lid fits and the same for the card inside the sauce jar with its tighter lid. Access is pretty easy and there is room for a “next gen” larger inner container down the road. The parts are in plastic boxes with labels facing out so I can quickly determine what’s there, and a few notations are on the box stickers to indicate their status wrt baking. (My parts database uses US town names starting with “A” for containers, thus the “AMORY” sticker).

I’m assembling several more of the same PCBs today and it would be nice if Whammy Central allows for pop-corning to have been the cause and the new boards to all pass FAT!