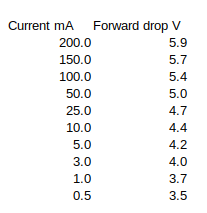

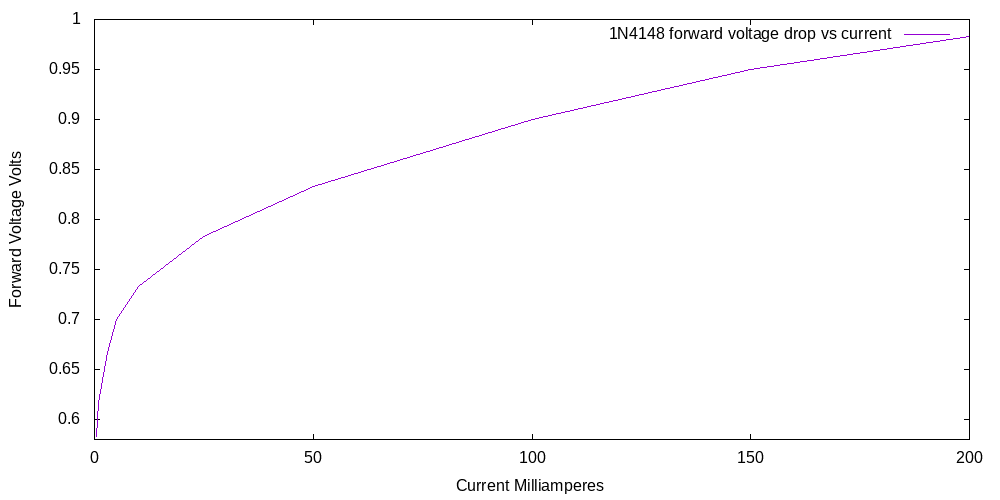

Sometimes we’re faced with a situation where a single DC supply is all that’s available but it’s is too much for part of a system and we really wish we had a lower voltage too. I knew diode forward voltage drop is a function of current (and temperature), but I didn’t appreciate just how variable this was until I got lazy and failed to look at a datasheet before I strung some 1N4148 diodes in series as a quick and dirty way to knock 12 volts down to nine. I figured that with the “standard” voltage drop across a silicon junction being .6 volts then 6x.6 = 3.6, and I knew if the current variation gave me around nine volts that would be OK for my application. Except when I tested this I found the variations at the currents the application involved would be all over the map. Here’s a table of what was measured across the six diodes at different values up to the absolute max current for the device:

Here is the same data but for a single diode:

So the per-diode voltage drop is only close to the .6 volts cited for silicon junctions at around one milliampere of current. At the upper current limit of the diodes the drop is very much higher. My application spanned a wide range of currents, so this diode string was hopeless (the client might have noticed a slight behavior change depending on operating mode, and I couldn’t tolerate that.) In my defense over the years I’ve treated diode voltage drops as something I wanted to minimize, making me not just a schottky diode bigot but one who would spend a hour finding the absolute lowest forward voltage drop for a given current. But I obviously developed no intuition at all for the more general cases.

Luckily I found a 7809 linear regulator in my junk box and I can simply carry on without having to order a part, but I thought this might be interesting to share. A high enough power zener would have been another solution.

As mentioned at the beginning, diodes change their behavior with temperature changes too and this is why you sometimes see a diode clamped under or near a power transistor: it’s change in behavior is leveraged with circuitry to keep the transistor from operating outside its safe temperature range. And some folks are able to use tables or perhaps a Taylor series with firmware to monitor voltage drops and use their simple diodes as thermometers.