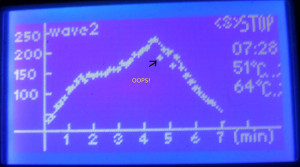

I’m still looking for clues about how this happened, but with yesterday’s soldering Chip and I did there was this terrible too-fast drop in temperature that explains the “dull” appearance of some of the solder joints. There were six breakout boards maybe 3/4 to 1″ square each sitting on a 1×4″ piece of circuit board in the middle of the oven tray. I’m aware this (plain T-962) oven is notorious for not performing well on large boards or boards outside the center of the tray, etc. But this was the first case of the temp control making a huge error at a critical moment. With one other batch I saw a mistake like you see below below and to the right of the one the arrow points to. Oh well, time to finish the fume hood and turn attention to some upgrades.